Views: 0 Author: Site Editor Publish Time: 2025-12-24 Origin: Site

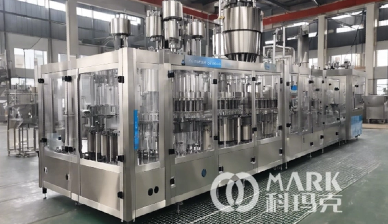

Water filling machines are essential equipment in the beverage and bottling industry, ensuring that water and other liquids are filled accurately, safely, and efficiently. However, like any industrial machinery, water filling machines require regular maintenance to perform at their best. Neglecting maintenance can lead to production delays, increased costs, and equipment failures. This guide provides a comprehensive step-by-step approach to maintaining your water filling machine to maximize efficiency, extend service life, and ensure consistent product quality.

Before delving into maintenance procedures, it is important to understand the main components and functionality of your water filling machine. Most modern water filling machines include the following key parts:

Filling nozzles: Deliver precise amounts of water into bottles.

Conveyor system: Moves bottles through the filling line.

Pumps and valves: Regulate the flow and pressure of water.

Control panel: Monitors and manages operational parameters.

Capping and sealing units: Ensure bottles are properly closed after filling.

Understanding these components allows operators to identify which parts require routine checks and maintenance.

Daily maintenance ensures that yourwater filling machine operates efficiently, maintains hygiene standards, and prevents minor issues from escalating into major problems. Following a structured daily routine helps maximize uptime and prolong the life of critical components.

Proper cleaning is crucial not only for operational efficiency but also for hygiene and product quality.

Exterior Cleaning: Wipe down all exterior surfaces using a clean, damp cloth to remove dust, water splashes, or residues from previous shifts. For stainless steel or metal surfaces, mild detergents can be used to prevent corrosion and maintain a polished appearance.

Filling Nozzles: The nozzles are the heart of the machine, ensuring accurate and consistent filling. Remove any buildup of mineral deposits, residues, or biofilm daily. For hard-to-clean nozzles, soak them in a mild cleaning solution or use small brushes designed for nozzle interiors.

Conveyor Belts: Inspect and clean conveyor belts to remove debris, spilled liquids, or particulate matter. Debris can cause uneven bottle movement, misalignment, or excessive wear on the belts and rollers.

Monitoring the machine during operation allows early detection of potential issues:

Flow Rates and Pressure: Regularly check the water flow and pressure settings to ensure they remain within manufacturer specifications. Sudden drops or spikes could indicate nozzle blockages, pump issues, or leaks.

Sensor Verification: Ensure that sensors, limit switches, and automated controllers are working correctly to prevent errors or downtime.

Noise and Vibration Monitoring: Listen for abnormal sounds such as grinding, squealing, or rattling, which may indicate loose parts, worn bearings, or motor issues.

Hygiene Compliance: In beverage production, preventing microbial growth is critical. Clean all surfaces and parts that contact water using food-grade sanitizers daily.

Preventing Contamination: Pay special attention to corners, joints, and hidden areas where water or residues can accumulate. Routine sanitization helps prevent biofilm formation and contamination of the filled product.

Weekly maintenance focuses on more detailed inspections and minor adjustments to prevent long-term wear and ensure optimal performance.

Conveyor Belts, Pulleys, and Gears: Inspect for alignment, tension, and signs of wear. Misaligned belts or worn gears can cause inefficient operation or damage other components.

Lubrication: Apply manufacturer-recommended lubricants to bearings, chains, and other moving parts. Avoid over-lubrication, which can attract dust or drip into the product area.

Leak Checks: Inspect pumps and valves for leaks, unusual vibrations, or changes in flow patterns.

Operational Verification: Ensure that all valves open and close smoothly without sticking, which maintains consistent water flow and prevents pressure fluctuations.

Mechanical Fasteners: Check all bolts, nuts, and screws to prevent loosening due to vibration.

Electrical Connections: Verify that connectors, wires, and terminals are secure to avoid unexpected shutdowns or electrical hazards.

Filtration: Ensure filters are clean and properly installed. Clogged filters can reduce flow, damage pumps, or cause nozzle inconsistencies.

Purity Standards: Confirm that incoming water meets the required chemical and microbial standards. Hard water or contaminated water can cause scaling, corrosion, or health concerns.

Monthly maintenance goes beyond daily and weekly checks, involving detailed inspection, calibration, and replacement of worn parts.

Filling Accuracy: Verify that each nozzle delivers the correct volume, adjusting as needed to maintain uniformity across bottles.

Sensor and Control Panel Checks: Confirm that electronic controls display accurate readings and respond correctly to input adjustments.

Motor Performance: Inspect motor temperature, vibration, and operation. Overheating or unusual vibration can indicate impending failure.

Electrical Cleaning: Remove dust or debris from control panels, enclosures, and wiring to prevent short circuits or signal interference.

Gears, Chains, and Bearings: Perform a thorough lubrication of all critical moving components.

Replacing Contaminated Lubricant: Remove any lubricant that has been contaminated by water, dust, or production residues and replace it with fresh oil or grease according to manufacturer recommendations.

Visual Inspection: Look for cracks, brittleness, or warping that could lead to leaks.

Replacement: Proactively replace worn or damaged seals and gaskets to maintain airtight operation, prevent leaks, and ensure hygienic conditions.

Quarterly maintenance is critical for ensuring the long-term reliability and efficiency of a water filling machine. While daily and weekly maintenance keep the system running smoothly, quarterly checks provide a deeper look at the machine's condition, allowing operators to prevent potential breakdowns and maintain consistent production quality.

A thorough inspection of all moving and critical components ensures that early signs of wear are detected and addressed before they lead to major failures.

Pumps, Valves, and Motors: Check for unusual wear, leaks, or signs of overheating. Ensure that pumps maintain consistent flow and pressure without excessive noise or vibration.

Conveyor Systems: Examine conveyor belts, rollers, and pulleys for alignment issues, fraying, or damage. Misaligned conveyors can cause bottle jams, uneven filling, or premature wear on belts and gears.

Capping and Sealing Units: Inspect these units to ensure precision and durability. Worn or misaligned capping mechanisms can lead to leakage or improper sealing, affecting product quality and safety.

A deep cleaning ensures hygiene and removes residues that could affect machine performance.

Internal Pipelines: Flush all water pathways to remove scale, biofilm, or mineral deposits that could block nozzles or reduce flow accuracy.

Use of Approved Cleaning Agents: Employ chemicals that are safe for food and beverage applications. Follow all safety protocols, including wearing protective equipment and ensuring proper ventilation.

Modern water filling machines often include automated control systems. Regular updates and testing ensure smooth operation:

Software Updates: Install any manufacturer-recommended updates to control panel software.

Automation Program Testing: Verify that programmed sequences, such as filling volume, conveyor speed, and capping timing, are operating consistently and efficiently.

Proactively replacing worn components reduces downtime and prevents unexpected breakdowns:

Spare Parts Inventory: Keep essential parts such as gaskets, bearings, belts, and seals in stock to enable quick replacements.

Scheduled Replacement: Even if parts appear functional, consider replacing those prone to wear based on manufacturer guidelines to avoid failures during peak production.

Beyond scheduled maintenance, implementing best practices helps maximize machine efficiency, safety, and longevity.

Operators should be trained not only in routine operation but also in preventive maintenance procedures:

Conduct refresher training sessions regularly, incorporating new safety protocols or updates in machine technology.

Encourage operators to recognize early warning signs of wear or malfunction, such as unusual noises, vibrations, or reduced filling accuracy.

Maintain detailed logs of inspections, repairs, and part replacements.

Use these records to track performance trends, identify recurring issues, and plan preventive interventions.

Keep the machine environment clean, dry, and free from dust or chemical residues.

Avoid excessive humidity or corrosive substances that could accelerate wear on mechanical and electrical components.

Address minor issues immediately instead of waiting for them to escalate.

Follow manufacturer troubleshooting guidelines carefully to avoid causing further damage to the machine.

By adhering to quarterly maintenance and incorporating these best practices, water filling machines can achieve maximum efficiency, minimize downtime, and ensure consistent product quality, ultimately improving overall operational productivity.

By following these step-by-step maintenance procedures, businesses can reap numerous benefits:

Extended Equipment Lifespan: Regular care prevents premature wear and ensures longer operational life.

Reduced Downtime: Proactive maintenance reduces unexpected breakdowns, keeping production lines running smoothly.

Improved Product Quality: Properly maintained machines ensure accurate filling, capping, and sealing, reducing product wastage.

Cost Savings: Preventive maintenance is more cost-effective than emergency repairs or machine replacement.

Energy Efficiency: Well-maintained pumps and motors consume less power, reducing operational costs.

Maintaining a water filling machine is a continuous process that requires attention to detail, routine inspections, and adherence to manufacturer guidelines. From daily cleaning and lubrication to quarterly overhauls, every maintenance step contributes to machine longevity, operational efficiency, and consistent product quality. By investing time and resources into proper maintenance, companies can ensure their water filling machines remain reliable assets in their production lines.

For businesses looking to enhance their water filling operations with high-quality, efficient, and durable machinery, Zhangjiagang Comark Machinery Co., LTD. offers a wide range of water filling solutions. Visit their website to explore their products, or contact their experts for professional advice and customized solutions tailored to your production needs.