| Availability: | |

|---|---|

| Quantity: | |

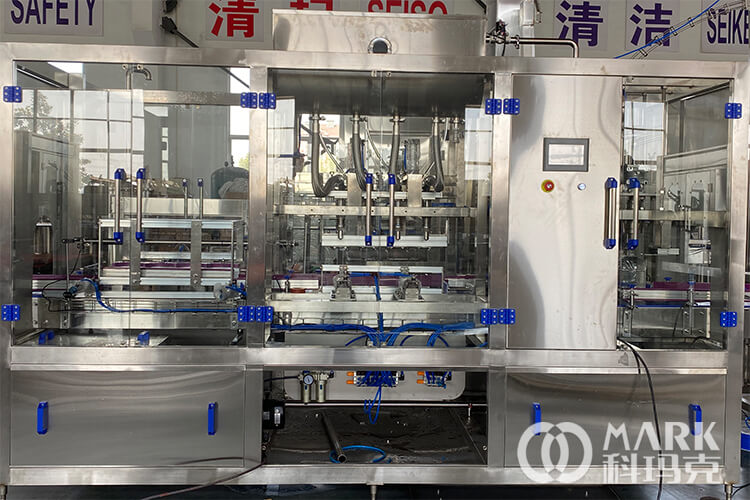

CGF 4-4-1

Comark

Product Description

5 Liter Mineral Pure Water Washing Filling Capping 3 In 1 Machine

The filling machine is suitable for 3-10L pure water, mineral water and other non-automatic liquid filling gas, its main features are:

1, Bottle red card is the bottleneck parts of method used, rotate 180 degrees, washing efficiency.

2, The use of fixed surface of the filling means filling quality, filling speed quickly.

3, The use of mechanical liquid level automatic control mechanism.

4, Filling valve, hydraulic cylinder and other parts of surface are in direct contact with high-quality stainless steel, corrosion-resistant, easy to clean, in line with industrial hygiene requirements.

5, The use of electromagnetic speed control motor, strong production capacity to achieve any adjustments.

6, Compact structure, convenient operation and easy maintenance.

| 3-10L big bottle filling machine | |||

| Model | CGF2-2-1 | CGF4-4-1 | CGF6-6-1 |

| Capacity (BPH) | 300BPH | 600BPH | 800BPH |

| Washing heads | 2 heads | 4 heads | 6 heads |

| Filling heads | 2 heads | 4 heads | 6 heads |

| Capping heads | 1 head | 1 head | 1 head |

Suitable Bottle shape | Round / square / Flat | ||

| Bottle material | PET / PE | ||

| Control system | PLC+Touch screen | ||

Automatic Bottle Inlet

Adopt air conveyor system with high efficient filter to feed bottle, this can keep the inside of the filling machine clean.

With bottle neck holding in the whole course and protect bottle block device.

The bottle feeding method with the air duct and the bottle feeding wheel directly connected.

The transition dial adopts a bottle-mouth stainless steel dial.

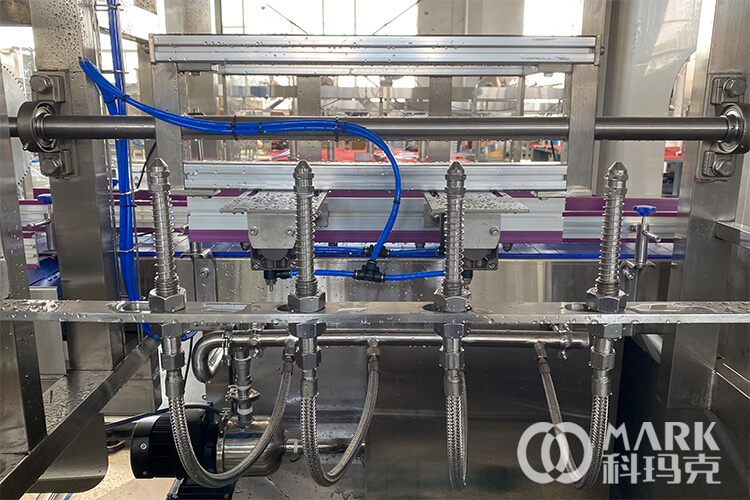

Automatic Rinsing Station

Auto-bottle rinsing machine absorb in high technology from aboard, by adopting gyration method on rinsing device, it can automatically complete working process from bottle entry, bottle rinsing, water removing to sanitized bottle out.

The grippers take the bottles from the inlet star-wheel, the bottle is turned upside down with 180 degree and cantred above a spraying nozzle which directs a stream of rinse water into the bottle.

Automatic Filling Machine

It is used in filling non carbonated water in plastic bottle .The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

High precision filling nozzle, PLC variable signal control, ensure high filling precision. Gravity filling, filling smoothly.

Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.

Automatic Screw Capping Machine

It connects with transporter and capping machine in line. Bottle is transported to capping machine by conveyor belt, after capping, passed by medium stand,transported to capping machine by conveyor belt, automatic cap-dropping equipment drops cap very well to seal cap. After sealing, conveyor belt puts out bottle.

The fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating the capping heads.

Comark can customize the suitable capping machine according to your requirements

|

|

|

|

| Filling water tank | Cap conveyor | Bottle conveyor | Electric box |

|

|

|

|

| Experienced engineer can help design the bottle shape according to your requirements and market demand | |||

Zhangjiagang Comark Packaging Machinery Co.,ltd is seated in the Yangtze River-Zhangjiagang City jingfeng Economic Development Zone, owns a 20,000 m² international standard workshop, Comark professionally researches, develops and manufactures beverage-packaging machines. Comark is high technology enterprise of Jiangsu Province, and best supplier of China beverage packaging machinery.

Since its founding 10 years ago. We are dedicated to the most advanced technology of beverage packaging machinery, and have always been conducting good up-to-date technical communication and exchange with leading Italy, Germany, France packaging companies. Some technology has filled Chinese packing technology gap.

Comark has a strong technology team for beverage packaging machine’s manufacturing. They are the source of Comark growing. There are now many food and beverage experts in Comark group. There are two food science technological doctors, five masters, and twelve high professional engineers. We provide marketing analysis, project budget, equipment technical configuration, train operators etc. We provide turnkey plant and relative service all the time.