| Availability: | |

|---|---|

| Quantity: | |

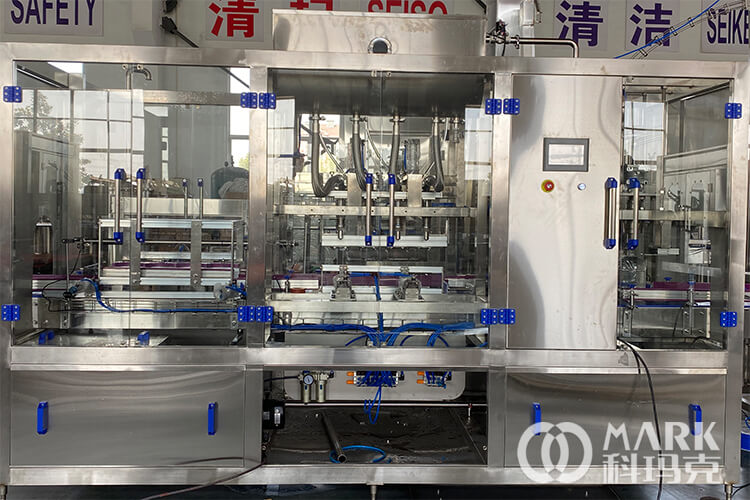

CGF 4-4-1

Comark

Product Description

The 5-Liter Mineral Pure Water Washing Filling Capping 3-In-1 Machine (model series: CGF2-2-1, CGF4-4-1, CGF6-6-1) is a high-efficiency integrated equipment designed for non-carbonated liquids like mineral water, pure water, and other similar beverages. Specifically engineered for 3-10L large-capacity bottles (PET/PE materials), this machine combines three core processes—bottle washing, filling, and capping—into a single streamlined workflow. It eliminates the need for separate equipment, saves factory space, and significantly improves production efficiency, making it an ideal choice for small to medium-sized bottled water factories, beverage manufacturers, and mineral water processing plants. With its compact structure and user-friendly operation, the machine meets industrial hygiene standards while ensuring stable performance for long-term use.

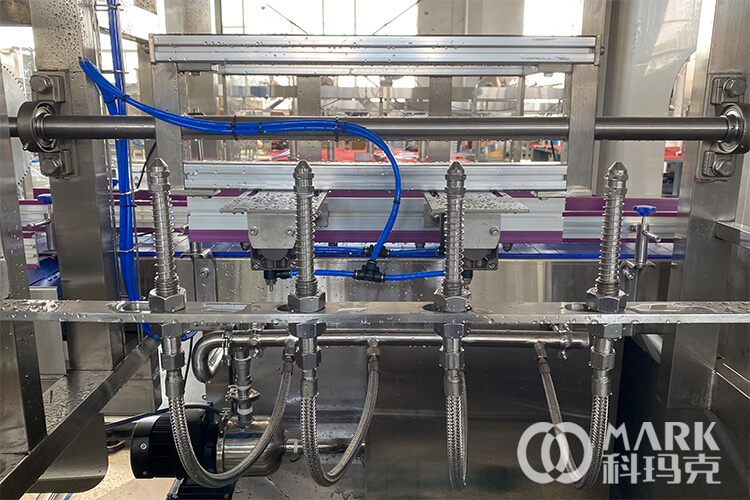

Adopting a bottleneck-holding design, the machine rotates bottles 180 degrees during the washing process. This unique mechanism ensures thorough cleaning of the bottle interior, removing residues and impurities effectively. The high washing efficiency reduces cleaning time while enhancing the hygiene level of finished products, laying a solid foundation for product quality.

Equipped with fixed-surface filling nozzles, the machine guarantees consistent filling quality and fast filling speed. The gravity filling method enables smooth liquid flow, avoiding splashing and foaming. This feature not only improves production throughput but also ensures accurate filling volume, minimizing product waste.

The integrated mechanical liquid level automatic control mechanism maintains a stable liquid level in the filling tank. This ensures uniform filling for every bottle, eliminating deviations caused by manual adjustment and enhancing production consistency.

All parts in direct contact with liquids—including filling valves and hydraulic cylinders—are made of high-quality stainless steel. This material is corrosion-resistant, easy to clean, and fully compliant with industrial hygiene requirements, ensuring the safety and purity of the filled beverages.

Powered by an electromagnetic speed control motor, the machine offers strong production capacity with flexible adjustability. Operators can easily modify the speed to match different production demands, making it adaptable to various bottle sizes and filling requirements.

The advanced PLC + Touch Screen control system simplifies operation. The intuitive touch screen allows for easy parameter setting, process monitoring, and fault diagnosis. Even unskilled operators can master the machine quickly, reducing training costs and operational errors.

Automatic Rinsing Station

Auto-bottle rinsing machine absorb in high technology from aboard, by adopting gyration method on rinsing device, it can automatically complete working process from bottle entry, bottle rinsing, water removing to sanitized bottle out. The grippers take the bottles from the inlet star-wheel, the bottle is turned upside down with 180 degree and cantred above a spraying nozzle which directs a stream of rinse water into the bottle.

Automatic Filling Machine

It is used in filling non carbonated water in plastic bottle. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles. High precision filling nozzle, PLC variable signal control, ensure high filling precision. Gravity filling, filling smoothly. Parts contacting liquid are all made of excellent stainless steel or food grade engineering plastic.

Automatic Screw Capping Machine

It connects with transporter and capping machine in line. Bottle is transported to capping machine by conveyor belt, after capping, passed by medium stand,transported to capping machine by conveyor belt, automatic cap-dropping equipment drops cap very well to seal cap. After sealing, conveyor belt puts out bottle. The fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating the capping heads.

The machine is certified by CE, ISO, SGS, ISD9001, and CNAS, meeting international quality and safety standards. Manufactured by Zhangjiagang Comark Packaging Machinery Co., Ltd.—a high-tech enterprise in Jiangsu Province with 10 years of experience in beverage packaging machinery—the product adopts advanced technology from Italy, Germany, and France, filling gaps in China’s packaging technology.

Professional technical team: 2 food science doctors, 5 masters, and 12 senior engineers provide technical guidance.

Customized services: Design bottle shapes based on market demand and customer requirements.

Comprehensive support: Offer market analysis, project budget planning, equipment technical configuration, and operator training.

Turnkey solutions: Provide full-set plant construction and after-sales maintenance services.